e-Cutter

DN125-DN315

Rehabilitate in the house installation at pipe dimensions DN125 / 5" to DN315 / 12" purely electric, i.e. without water tank or compressed air. The robot is therefore ready for use 365 days a year - thanks to the wireless control unit even from a warm vehicle or a shady place!

e-Cutter

DN125-DN315

Rehabilitate in the house installation at pipe dimensions DN125 / 5" to DN315 / 12" purely electric, i.e. without water tank or compressed air. The robot is therefore ready for use 365 days a year - thanks to the wireless control unit even from a warm vehicle or a shady place!

Downspout rehabilitation

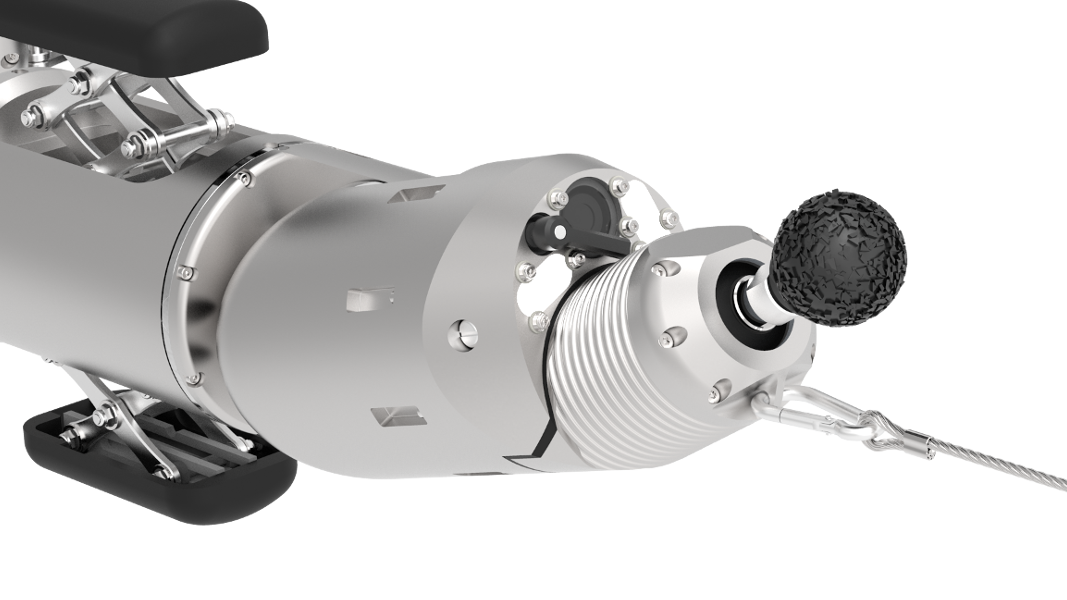

To secure the robot in the downspout this is quickly and easily fixed with a steel cable through an eyelet on the housing of the milling motor!

This means that the robot can be secured or pulled at any time.

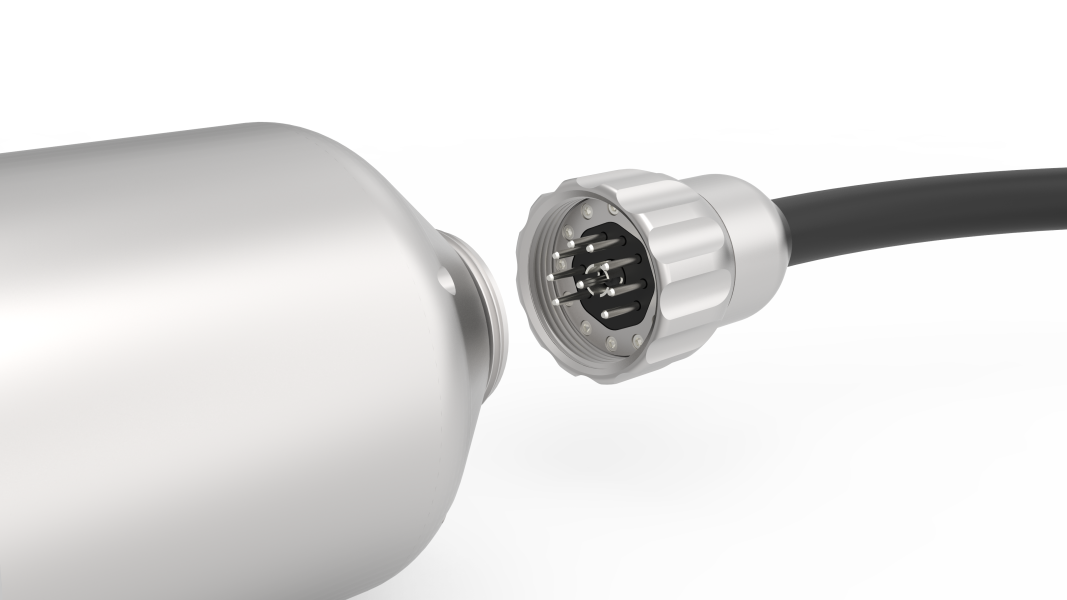

Full compatibility

100% compatible with the e-Components system.

Plug-and-play connection with the e-Base as well as various cable reels with push cables in different stiffnesses and lengths. Optimal conditions for every application - whether robot or camera travel!

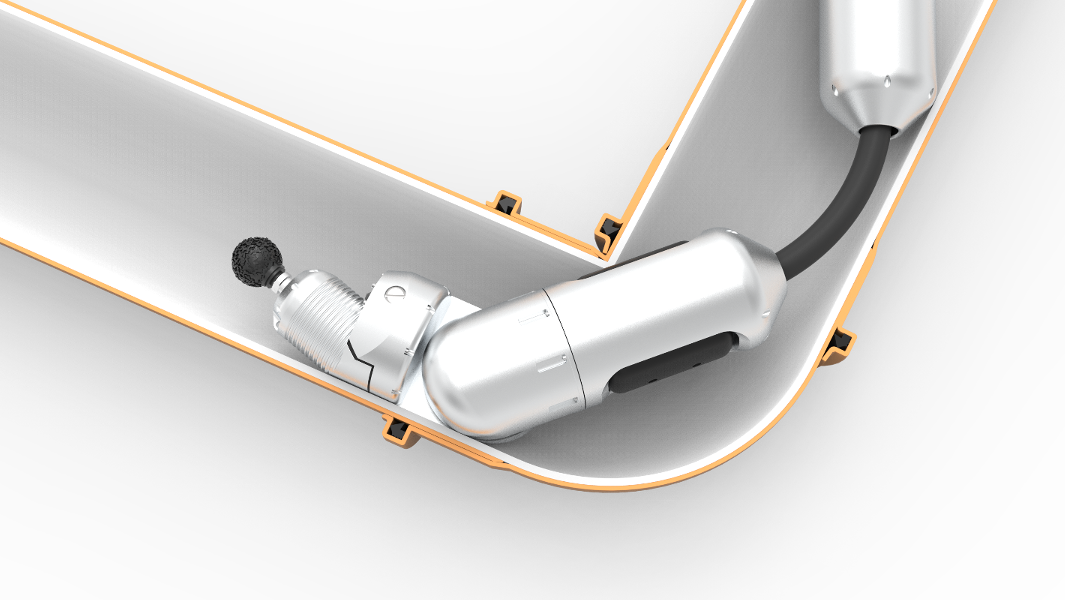

Arc capable

The robot can be operated up to DN 250 without adapter. Therefore, it is particularly arc capable!

87° bends from nominal width DN150 / 6"

45° bends from nominal width DN125 / 4"

Full HD in real time

The robot is equipped with a Full HD camera (1920x1080p) and therefore offers the best live video image in the world market!

The full resolution can be sent wirelessly to the control unit in real time.

Compatible with the wireless operating unit

the e-Components series (part of the e-Base)

Großer

Arbeitsbereich

Nominal sizes up to DN250 / 9" completely without adapter!

With quick-change adapters up to DN315 / 12".

Compliant with oval cleaning openings.

Rapid commissioning

From zero to full operational capability in less than 60 seconds!

The Connection of the equipment within e-Components system as well as the start-up procedure are very simple and quick to perform.

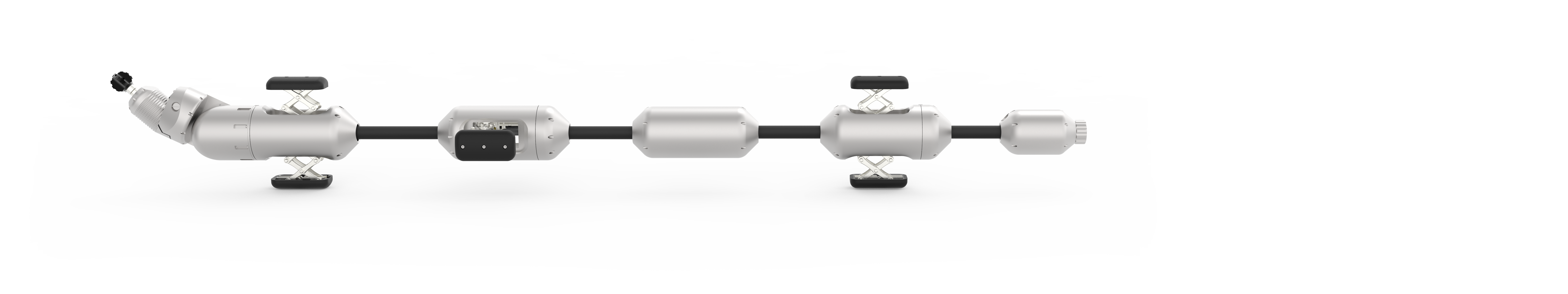

Swap and recombine modules!

From the very beginning, we have thought one step ahead and developed our products in a modular way. The equipment in the e-Components series consists of compact modules that can be replaced in a matter of minutes in the event of damage or routine servicing.

The individual modules can also be connected in different arrangements to obtain the most suitable robot for every situation!

That's how

service & repair

works with

pipe robox

1. Take the device out of operation and disconnect it from the supply unit

2. You unscrew the module to be serviced/repaired and remove it

3. Remove the new module from the pipe robox

4. Unscrew the plastic protective covers of the new module and screw them to the module to be serviced/repaired

5. Observe the enclosed instructions of the new module, carry out all steps of the instructions

6. Now screw the new module to the equipment at the same place where the module to be serviced/repaired was originally located

7. Your device is now ready for use again

8. Pack the module to be serviced/repaired into the pipe robox and send it to us by Fedex, DHL, TNT or other transport company of your choice

Technical product sheet

The current Product data sheet here for download

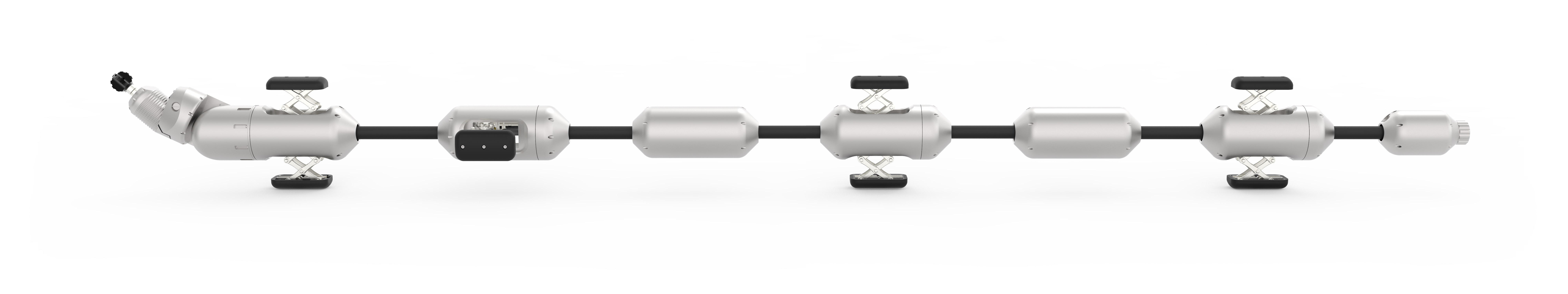

Your choice

Short or long? Who has the choice.

Here in comparison...

We offer you the e-Cutter DN125-DN315 into short as well as long version !

We will be happy to advise you on the differences between the two versions and which robot is best suited to your needs and your rehabilitation team.

e-Cutter DN125-DN315 infinity

Pros

Pros

- infinite feed (patented drive technology) for continuous movement in the work area

- automatic movement (also with cruise control)

Cons

- slightly more weight than the short version

- slightly longer design due to more segments

e-Cutter DN125-DN315

Pros

Pros

- less weight than the long version

- shorter, more compact design

- automatic movement (also with cruise control)

Cons

- 5cm / 2" feed, then short break (as known from robots from other manufacturers on the market)

Development according to the requirements of the industry!

In the course of accompanying rehabilitation teams all over Austria, we not only got to know the different systems of pipe rehabilitation, but also different approaches and working techniques. Although these often differ considerably from one another, they all have one thing in common: they all require equipment that enables them to work efficiently, cleanly and quickly. From the many requirements and wishes of the renovators, we developed concepts and produced prototypes of our renovation robots. In current series production, these offer the following functions:

Other systems mostly describe the performance of their robot systems with the input power of the compressors. Unfortunately, only a fraction of the mentioned input power arrives at the end of the hose. In addition, it is known that in most cases only a small part of the maximum power is used anyway, since on the one hand the working environment must be taken into account and also in order to work cost-efficiently.

Pipe Robotics - Power transmission at a high level

Our data are 100% authentic, as we use purely electric drives and can therefore guarantee that the maximum level of performance is always available. In all comparisons on real work sites, the Pipe Robotics system always came out on top in terms of performance and continuous load capacity! Thanks to the electric actuators, the device knows at all times what loads are acting on the system or where there are rotations in the limit values and displays this in real time on the control unit.

Every system has its limits!

Originally developed for the DN150 / 6" - DN315 / 12" range, this milling robot can be used in the linered pipe of that dimensions up to 87° bends (also 2x 45°). The device can also be used in DN125 / 4" pipes, but there up to max. 45° and depending on the liner used!

In order to avoid possible snagging of the robot when retracting during operations, we recommend URGENTLY to remove larger wrinkle formations, especially on the inside of bends, with the cutter already when driving over the lined pipeline.

If you would also like to convince yourself of the excellent sheet travel of our system, we would be happy to arrange a product demonstration with you!

Due to the high-resolution camera image in the head of the device (1080p Full HD) - by the way, a world first for a rehabilitation robot - the logging and documentation of the operation can, if desired, also be carried out without the need for a subsequent and additional camera inspection, but directly during the rehabilitation work!

This saves time and money. In addition, a complete and perfect documentation is indispensable to document the proper execution of your work and proper refurbishment and to be able to avert possible complaints.

Of course, all digital documents are on your control unit clearly summarized and ready for transfer via USB interface, W-LAN or LAN connection to your local network as soon as the device is back at a branch office or in the car - you do not need a network or internet connection to work! The device works completely autonomously (offline).

The The hook incorporated into the motor housing provides an attachment point for a wire rope to lower or secure the robot.

If efficiency during milling is particularly important to you and you want the longest possible continuous feed, then choose the "infinity" version of our robot and benefit from our patented drive technology!

The robot worms through the pipe in exactly the same way, but an additional feed segment compensates for these movements and a smooth, consistent forward/reverse motion is made possible. For you, this means an infinite feed!

Still questions?

We are gladly available for Questions and detailed information to all offered Pipe Robotics system devices anytime.

Comprehensive consultation and training are essential to understand and operate the systems optimally.