MP-Cam HD

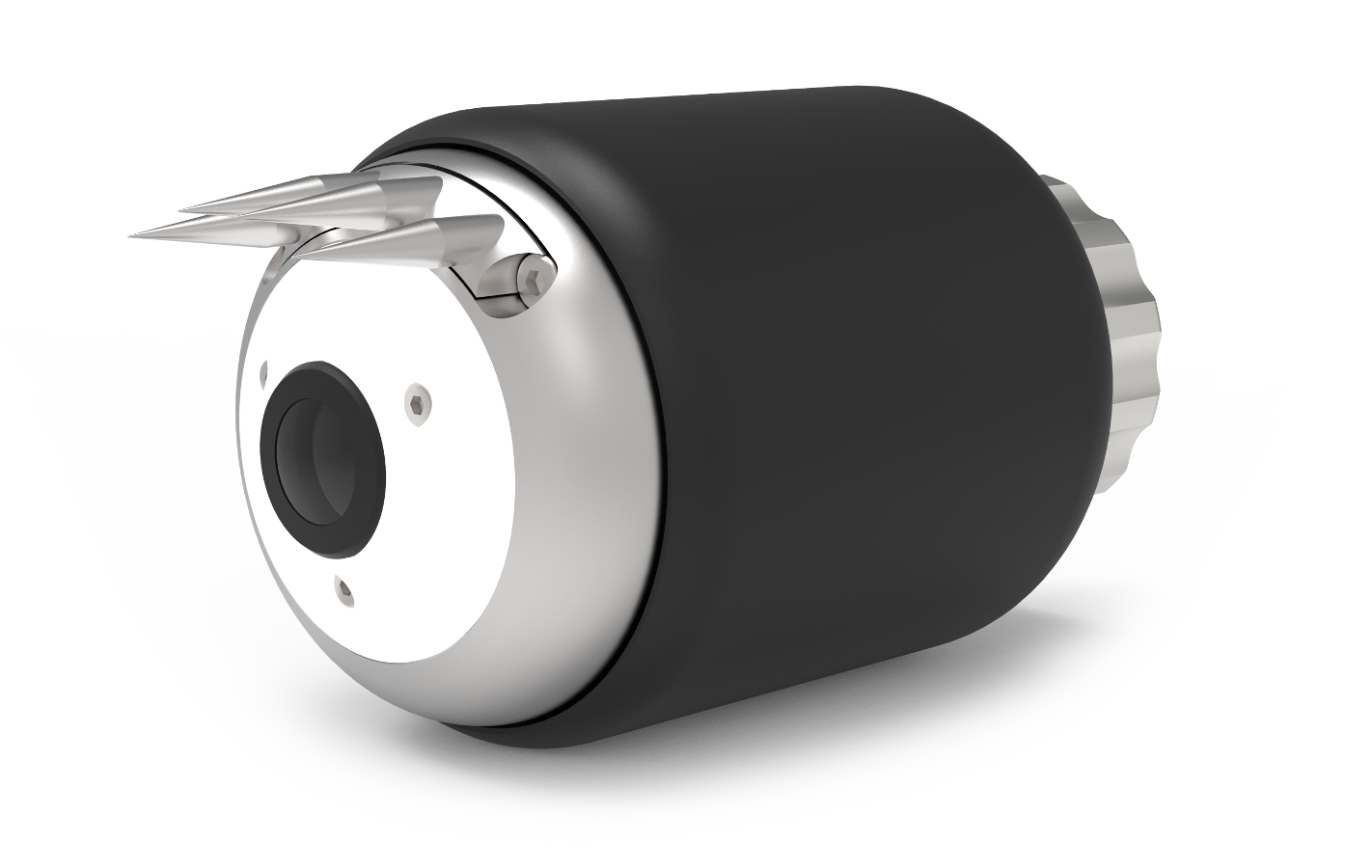

With this multipurpose Full HD camera for the base unit of the e-Components series it is quickly and easy possible to record and document the rehabilitation process as well as to carry out visual inspections for the preliminary or follow-up inspection of the house installation, and a calibration hose can also be pierced to improve the steam flow during steam lining, for example.

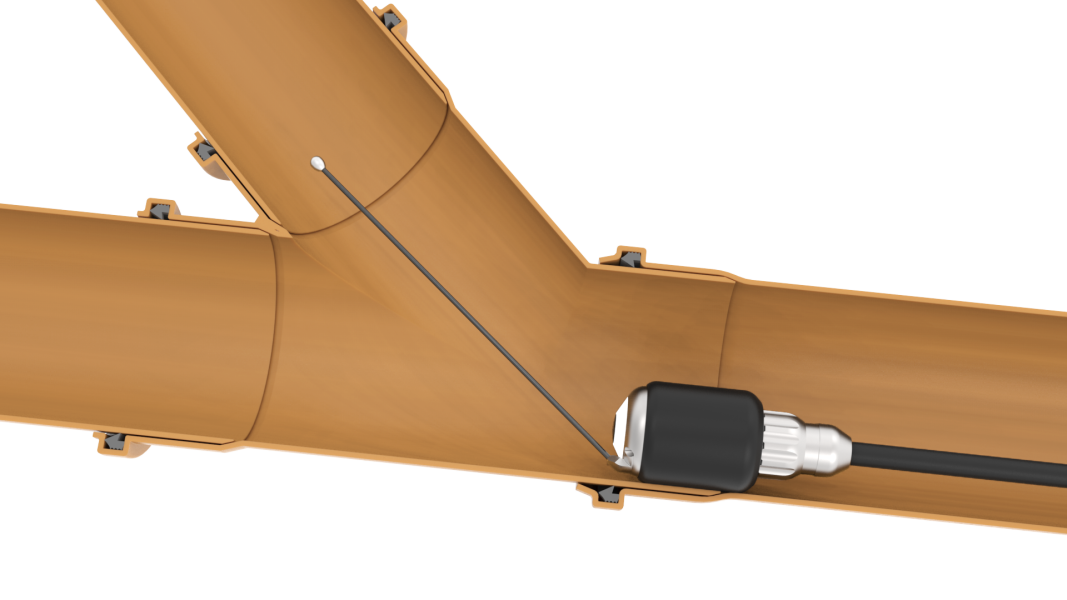

Navigate into branches

Thanks to the branch mandrels in various lengths in combination with the infinite rotation, the camera can be pushed specifically into branches easily.

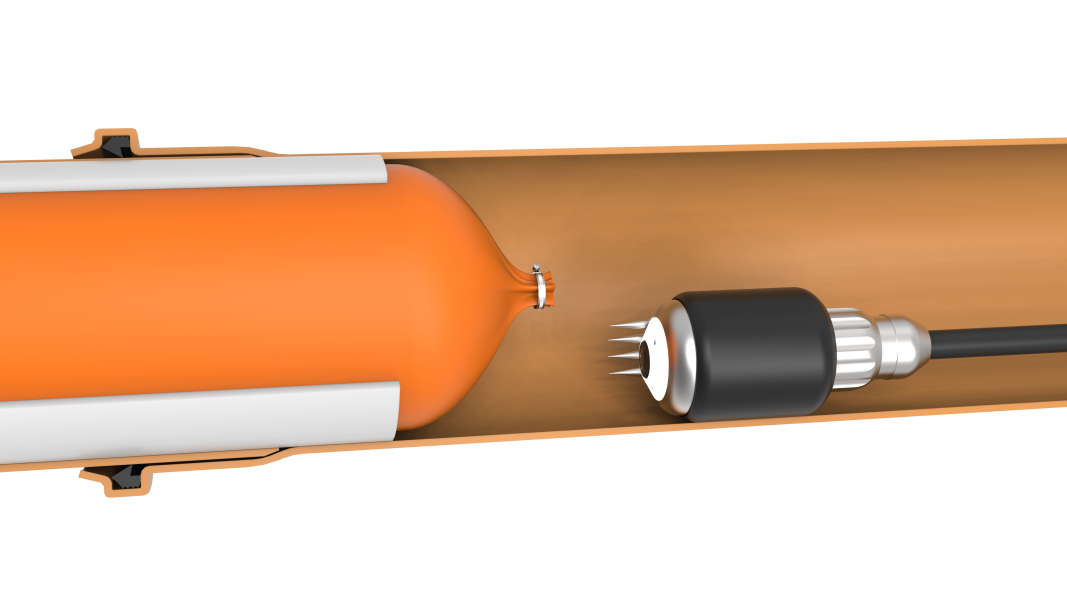

Pierce the calibration hose

With the piercing mandrel a calibration hose be pierced after inserting the lining tube in order to improve the steam flow during steam lining.

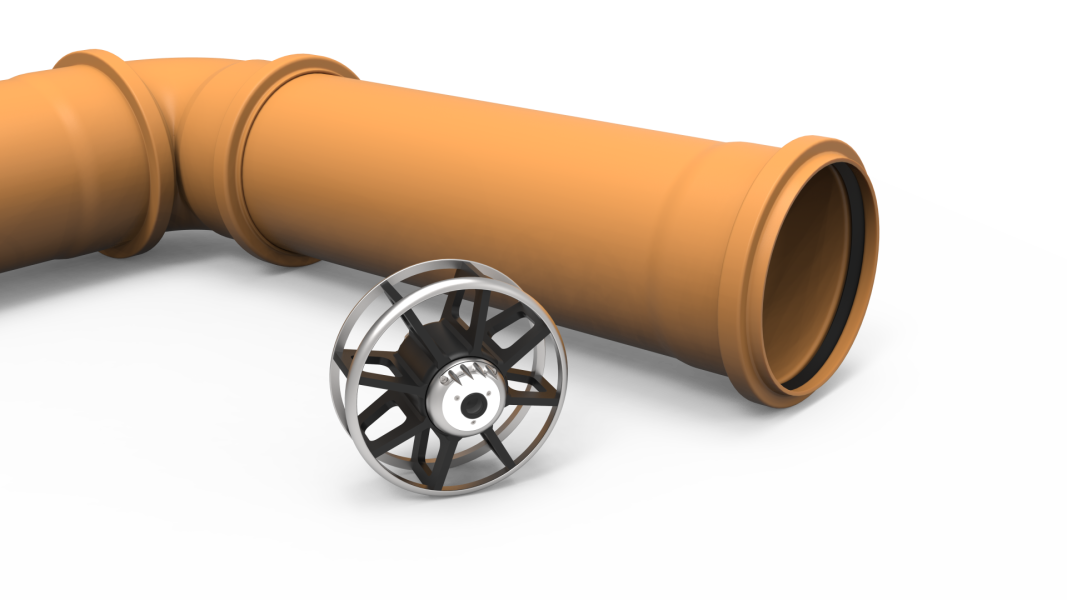

Adapter attached in seconds

Full compatibility

Plug-and-play connection with the e-Base as well as various cable reels with push cables in different stiffnesses and lengths. Optimal conditions for every application - whether robot or camera travel!

Wireless control

Development according to the requirements of the industry!

Equipped with a high resolution digital camera this attachment is an optimal extension for your system!

Play the recorded photos and videos in realtime in your deployment logs and easily add to your records. Camera inspections help you get an idea of the extent of the damage, inspect lined pipes before milling work and view and inspect all work after the rehabilitation is complete.

The wide-angle lens specially developed by Pipe Robotics saves you the use of an error-prone swivel head - you have the optimum overview in the sewer pipe!

The unwinding of the pushing cable is measured - the length of the pipelines or rehabilitation sections can thus be optimally determined.

A gyroscope integrated in the camera head detects inclinations in the blank and logs them.

Several system-compatible units for different pipe dimensions are available and can be connected ready for operation in just a few steps.

Due to the possibility of 360° rotation as well as the inclined threading mandrel (optional), control is possible easily and without complications in the case of taps!

By simply switching from the steering mandrel to the carbide mandrel, the calibration hose can be opened quickly and easily.

Still questions?

We are gladly available for Questions and detailed information to all offered Pipe Robotics system devices anytime.

Comprehensive consultation and training are essential to understand and operate the systems optimally.

Available for you soon!

You are interested an der MP-Cam HD?

We will be happy to add you to the waiting list and keep you informed about the current status of the development work!